ACRI, through strategic researcher partners at the University of Wollongong (UoW) led by Professor Huijun Li, are meeting the needs of the Pilbara heavy haul operators by studying how to safely weld rails with optimised mechanical properties.

The heavy haul iron ore network in the Pilbara holds the world record for heaviest axle loads and as such, advanced steel grades called head-hardened steels have been used to build the tracks.

These steel grades rely for their sound mechanical properties on a microstructure called Pearlite. It is comprised of incredibly fine layers of two atomic phases of steel, one Ferrite (softer phase) and the other Cementite (hard phase). These alternating layers, with a thickness of tens of nanometres, produce a combination of hardness and toughness that offers excellent wear resistance.

To inform safe welding practices under these properties, a fundamental study of how the Pearlite grows during cooling post-weld is a critical. Experiments using High Temperature Confocal Microscopy – Differential Thermal Analysis (HTCM-DTA), a technique developed at UoW, has been applied to directly measure the growth rate.

In the attached two-part video, the growth of Pearlite is observed, and then highlighted through an image analysis technique. A number of Pearlite colonies are observed to form and then grow, transforming the higher temperature steel phase Austenite in the process.

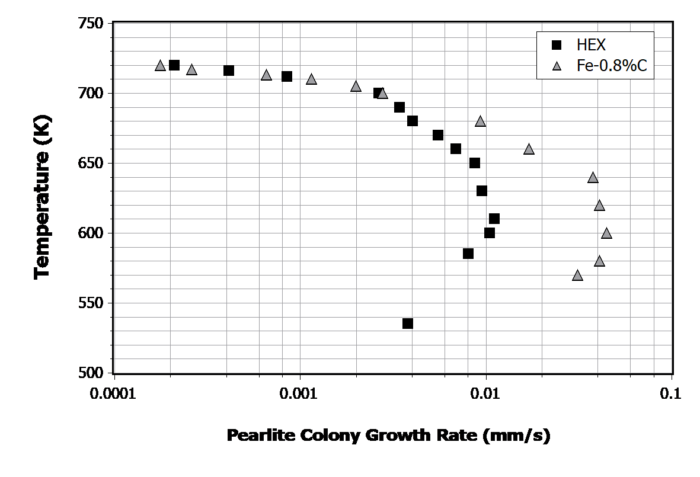

This data generated for two alloys, HE-X a commercial rail steel and a pure Iron-0.8%Carbon, are shown in the attached Figure. The growth rate of Pearlite is a strong function of temperature; and below a certain temperature the growth rate of HE-X diverges from the binary alloy.

The cause of this is the presence of Silicon, Manganese and Chromium in HE-X, which slow the rate at which Pearlite can grow. Gaining an understanding of how various elements control the growth is an essential component of understanding how we optimise the resulting mechanical properties, and improve the efficiency and safety of Pilbara heavy haul operations.